PVC foam sheets, also known as PVC foam boards or expanded PVC sheets, are lightweight and versatile materials commonly used in a variety of applications across industries. Here's an overview of PVC foam sheets:

Composition

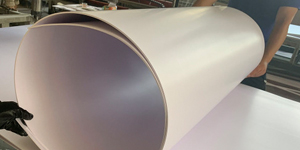

PVC foam sheets are made from polyvinyl chloride (PVC), a thermoplastic polymer, through a process of foaming or expanding the material. This results in a lightweight, rigid, and closed-cell structure with a smooth surface finish.

Lightweight & Rigid

Despite their lightweight nature, PVC foam sheets are rigid and durable, making them suitable for structural applications where strength and stability are required. They offer a high strength-to-weight ratio, making them easy to handle, transport, and install.

Weather Resistance

PVC foam sheets are resistant to moisture, chemicals, and weathering, making them suitable for both indoor and outdoor applications. They do not rot, swell, or degrade when exposed to water or harsh environmental conditions, making them ideal for outdoor signage, displays, and construction projects.

Thermal Insulation

PVC foam sheets offer excellent thermal insulation properties, helping to regulate temperature and energy costs in buildings. They have low thermal conductivity, which means they can effectively prevent heat transfer, making them suitable for applications such as wall insulation, HVAC ducts, and refrigeration units.

Chemical Resistance

PVC foam sheets are resistant to most chemicals, oils, and solvents, making them suitable for applications where exposure to harsh substances is common. This feature makes them ideal for use in chemical processing plants, laboratories, and industrial settings.

Versatility

PVC foam sheets can be easily cut, routed, and fabricated using standard woodworking tools, allowing for customization and intricate designs. They are available in various thicknesses, colors, and surface finishes to suit different project requirements.

Common applications for PVC foam sheets include:

Overall, PVC foam sheets offer a combination of lightweight, rigidity, weather resistance, and versatility, making them a popular choice for a wide range of applications across industries.